A Finnish experimentation project has made cross-laminated timber construction more productive and creative by using digital modeling.

The office of &’ [Emmi Keskisarja & Janne Teräsvirta & Company Architects Ltd] looks rather like a prototype workshop. Intriguing scale models, a 3D printer, and a small CNC machine all give clues about the architects’ current project. They’re determined to make wood construction more collaborative and creative using digital technologies and cross-laminated timber (CLT).

Plenty of Room for Improvement

“I’m going to present our KIRA-digi project at WDBE 2018 in September. Incidentally, our wooden installation will be on display during Helsinki Design Week,” says Keskisarja. “We want to communicate with the public, not just within our professional circles, as architects typically do. The theme of the week is trust, something that’s missing in today’s construction.”

Keskisarja and Teräsvirta realized that the entire construction process is flawed. Sub-optimization, isolated participants, and short-term thinking dominate. There’s very little emphasis on collaborative concept development and creativity at the early stages of a project.

In building production, we fall back to the same standard solutions. Digital design processes have failed to improve the practice as much as they could have. “Collision detection” is a BIM term that aptly describes the current process, with its focus on errors rather than collaboration.

Research and Practice Coming Together

The architects decided to start re-thinking the construction process. They chose wooden construction as a case study for their experimentation. Keskisarja had previous experience in digitalizing timber design and manufacturing. She’s working on her PhD on how to improve design using system theory. Teräsvirta has a history of world-renowned projects as a founding partner of ALA Architects. He also appreciates wood as a building material.

“We wanted to study how things could be done better,” says Teräsvirta. “Wood construction is gaining popularity in Finland, but it is done unimaginatively. You could argue that we build concrete buildings of wood.”

Before starting the KIRA-digi project, the architects had already collaborated with three master cabinetmakers: Tommi Alatalo, Antrei Hartikainen, and Heikki Paso. They realized that cabinetmakers use the same design software as they do, only on small-scale woodwork. In the experimentation, they scale up the joiners’ details to building frames and cross-laminated timber. That opens new architectural and structural possibilities.

The prototypes that Keskisarja and Teräsvirta are working on are far from what you’d expect from a typical wood construction. The cone-shaped, organic-looking prototypes showcase the possibilities of modern CNC milling used in a building scale.

From Prototypes to Managing Design and Production

Finnish cross-laminated timber mills have expensive five-axis CNC machines that can fashion almost any imaginable joint at millimeter precision. However, they mostly use their fine machines to carry out bulk work, and charge by the cubic meter. The prototypes that Keskisarja and Teräsvirta have designed explore the possibilities of CLT in a far more elaborate way.

“Using digital tools, architects can regain their role as a master designer, taking responsibility for tasks that are now in no man’s land. We can now be more than form-givers and functional designers; we can plan and optimize the production process,” Keskisarja envisions. “Collaborating with the manufacturers and contractors, we can start creating healthy, sustainable, and more affordable buildings.”

The prevailing construction technology has led to technically complex buildings that don’t always function as expected. Mass timber structures are simple, flexible, and easy to understand.

Keskisarja and Teräsvirta don’t want to use the new process and technologies for one-off projects. Digital technologies and robotics enable mass customization of any type of project, be it, for example, an apartment house, a single home, or a school. Timber is not the only choice, either. It’s great for structural uses, but facades can be made of glass or other weather-resistant materials. Hybrid solutions combine the best features of materials optimally.

Results Everyone Can Benefit From

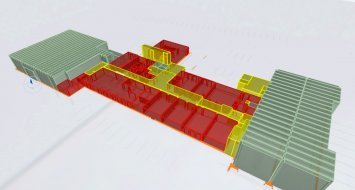

The KIRA-digi experimentation heralds a new industrial process devised with systems theory, digital information flow, and CLT/CNC technologies.

The project will deliver digital and physical prototypes and process models. The results will be publicly available for every interested party to study and use in their business. The existing design and manufacturing software is sufficient for the improved process, the architects believe. Their firm will use and further develop the results in their architectural practice.

Teräsvirta sees a change of thinking emerging in the construction industry: “We have discussed our ideas with many professionals, including contractors, and received very positive feedback. We’re living exciting times in our industry. There’s definitely momentum for change.”

Other news

The Winning Teams at the AEC Hackathon Helsinki

The AEC Hackathon on September 7-9, 2018, was a part of Housing Fair Finland’s City Living...

City Development with Interactive 3D Models

The Finnish city of Hyvinkää has developed a unique internet service for collaborative 3D ...

BIM Meets Reality on the Construction Site

BIM models are mostly used by foremen on construction sites. But what if they could be mad...

How BIM Can Serve Building Owners

Building Information Models typically end their active life after the construction phase. ...